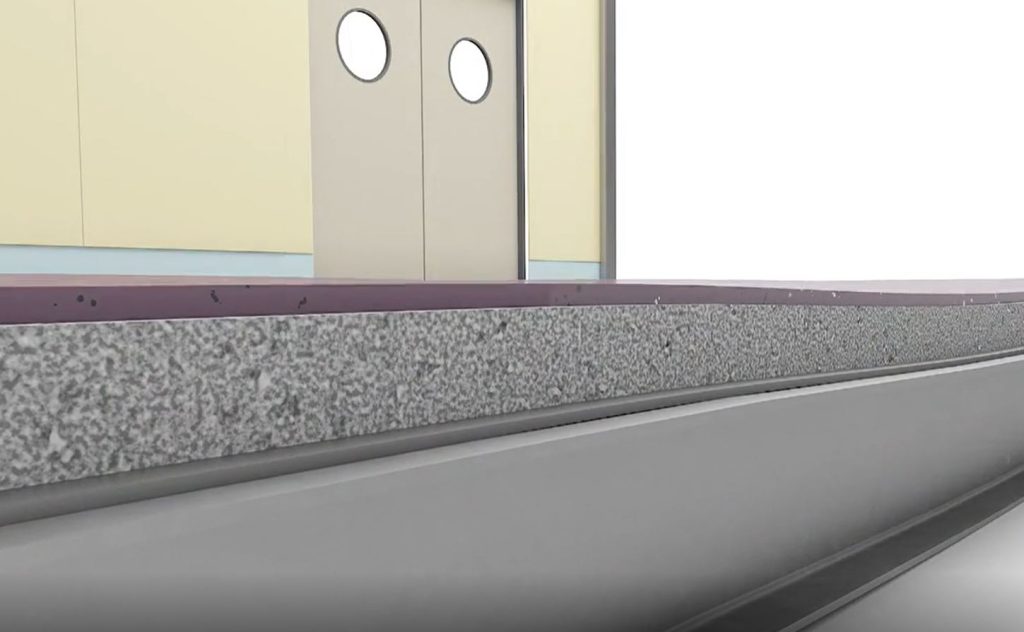

KAEFER has long and extensive experience in surface protection and carries out all types of surface protection projects in the energy industry. KAEFER has the expertise, methods and equipment within the surface protection discipline to ensure specified quality and to help extend the life of the client’s assets.

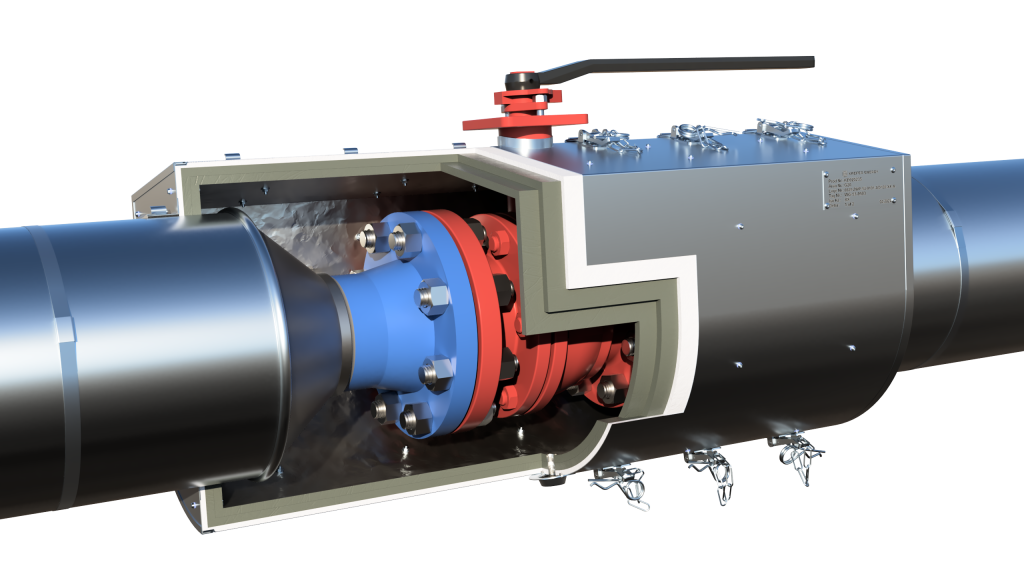

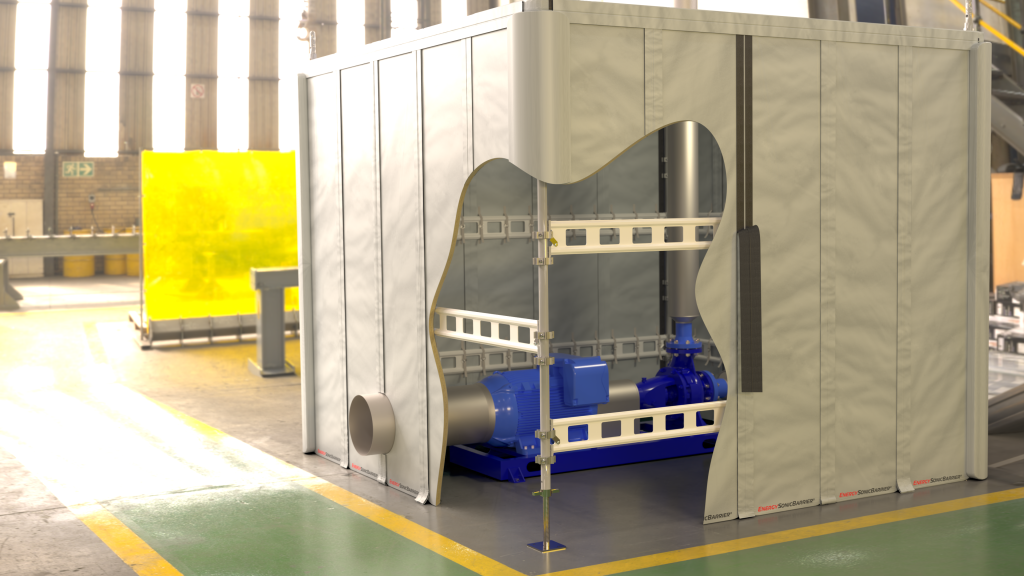

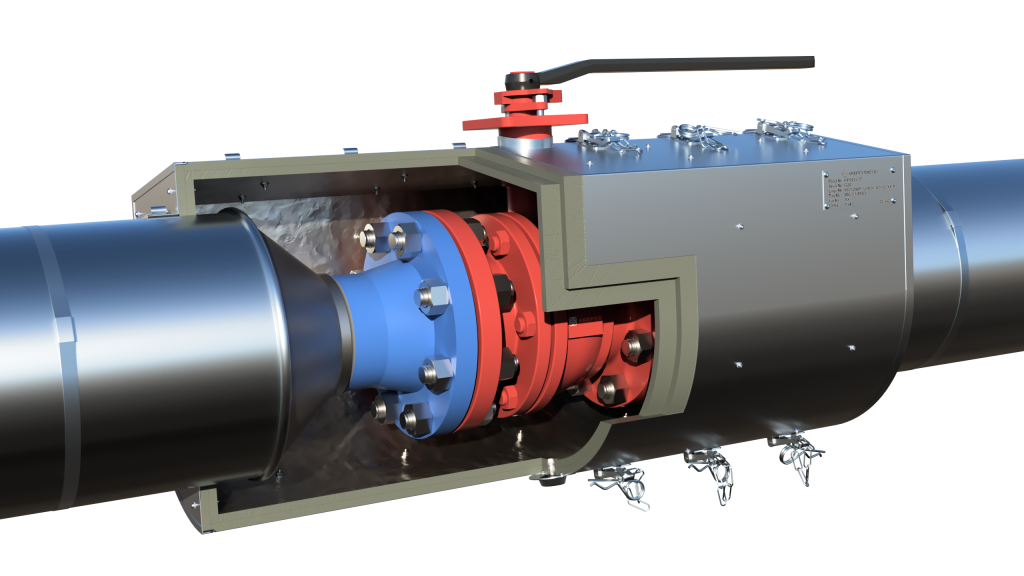

Fire insulation

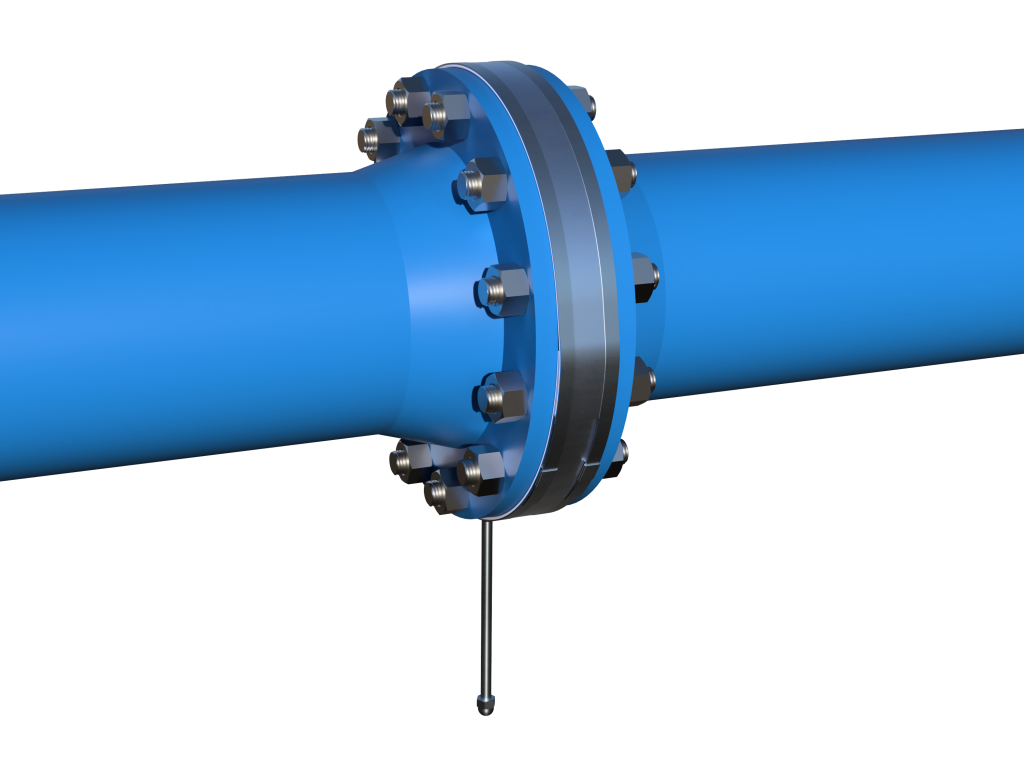

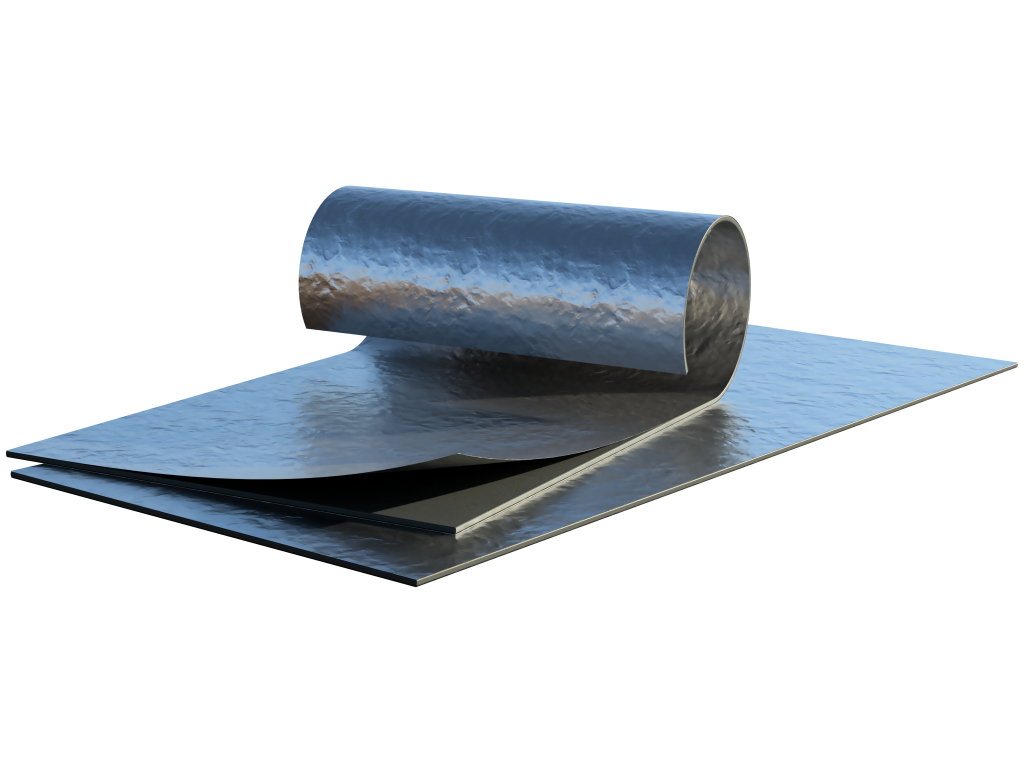

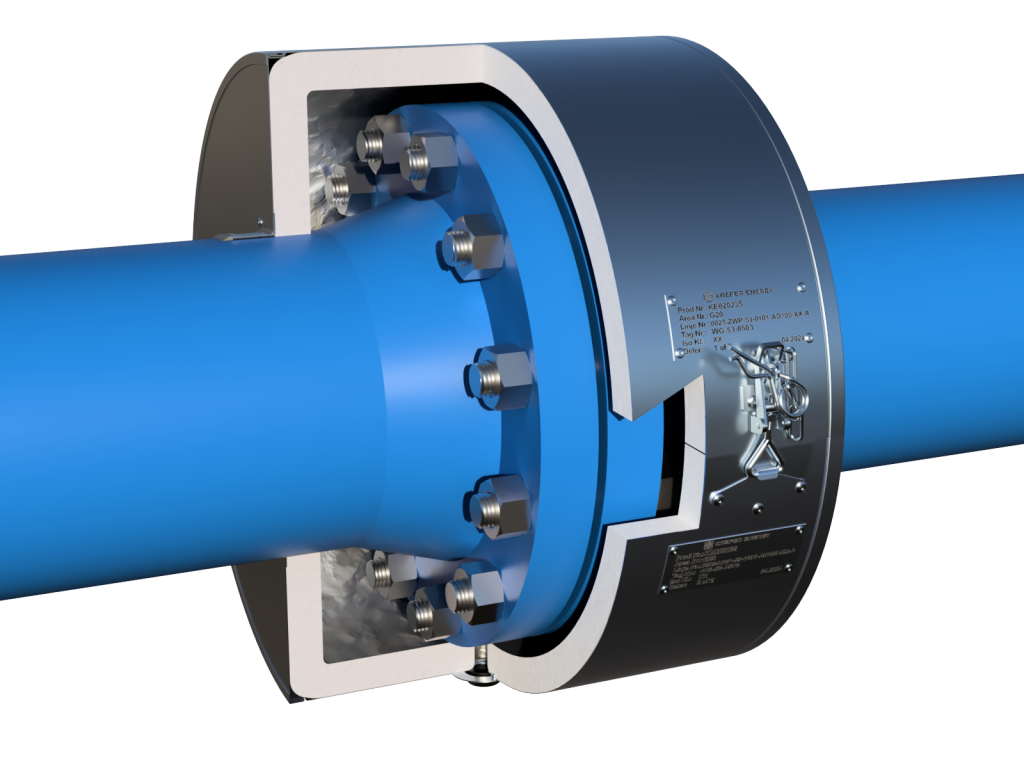

ENERGY Cryocover™

Liquefied Natural Gas (LNG) is a type of cryogenic liquid that can be flammable and can therefore cause jet fires (gas leak ignition). As part of the safety system on LNG vessels, it is required that valves and flanges contain insulation material that protects against both jet fire and cryogenic leakage/spills.