KAEFER offers robotic services in relation to ISS disciplines with the aim of influencing and changing traditional methods to more automated and efficient technology. The integration of robotic technology into ISS deliveries has a significant positive impact on various operational aspects in terms of safety, efficiency, improvements and costs. The use of robotic services also helps to reduce the risk of manual labour in dangerous or challenging environments. The integration of robotics also has a long-term sustainability perspective and reduced environmental impact in the form of less waste, optimised energy consumption and better resource utilisation.

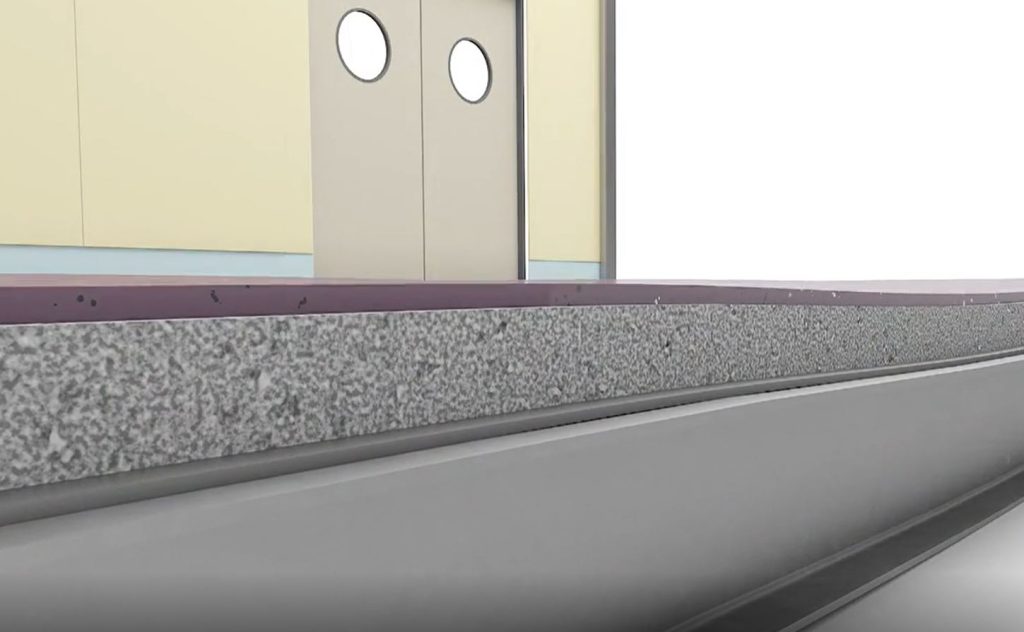

Fire insulation

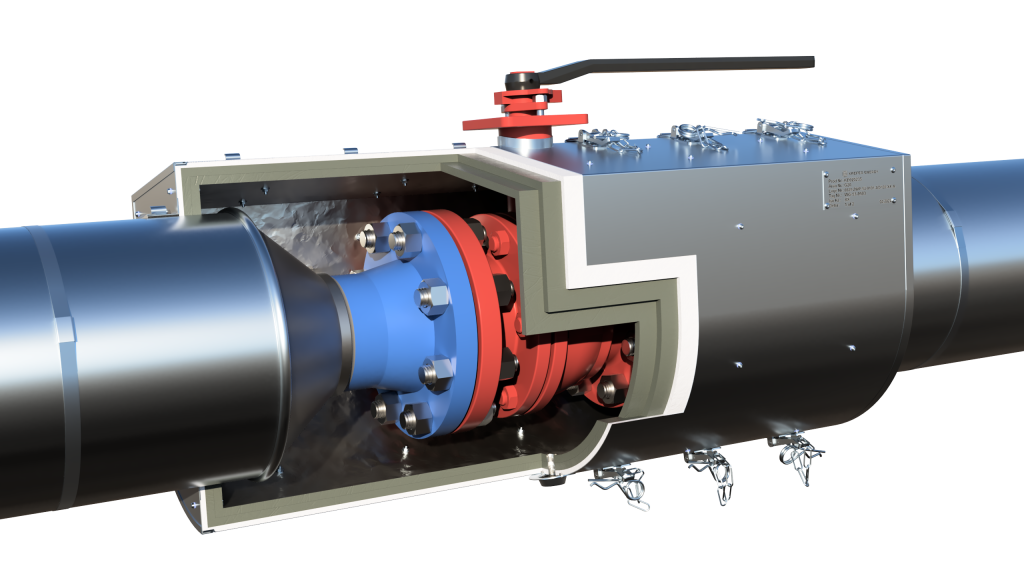

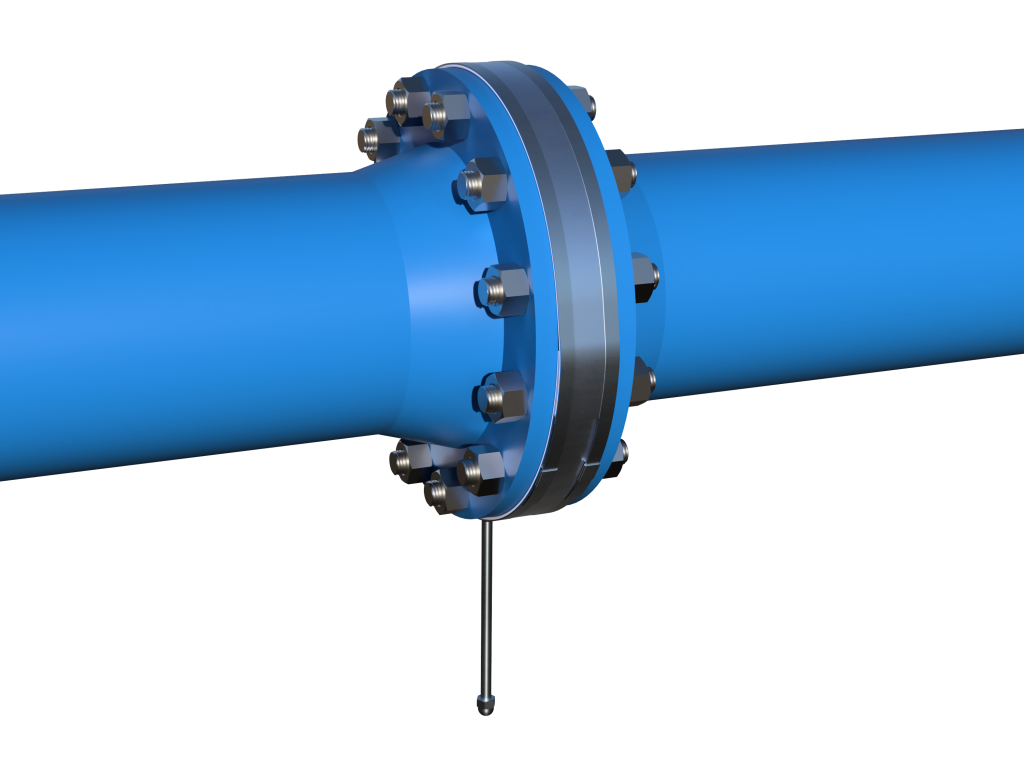

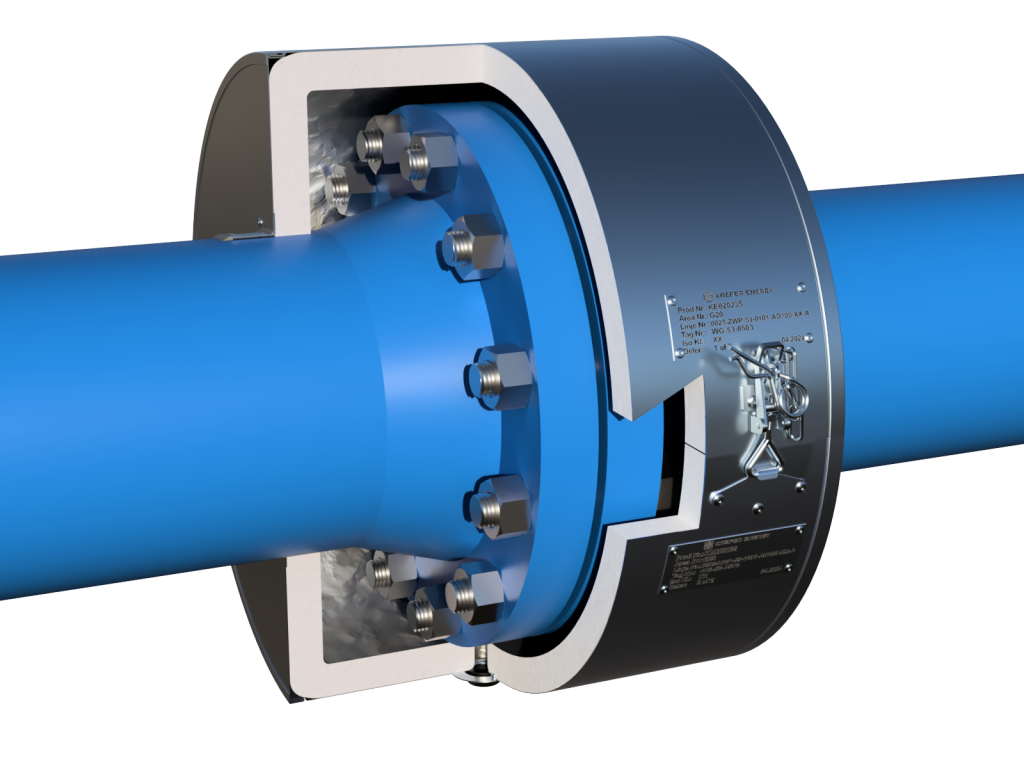

ENERGY Cryocover™

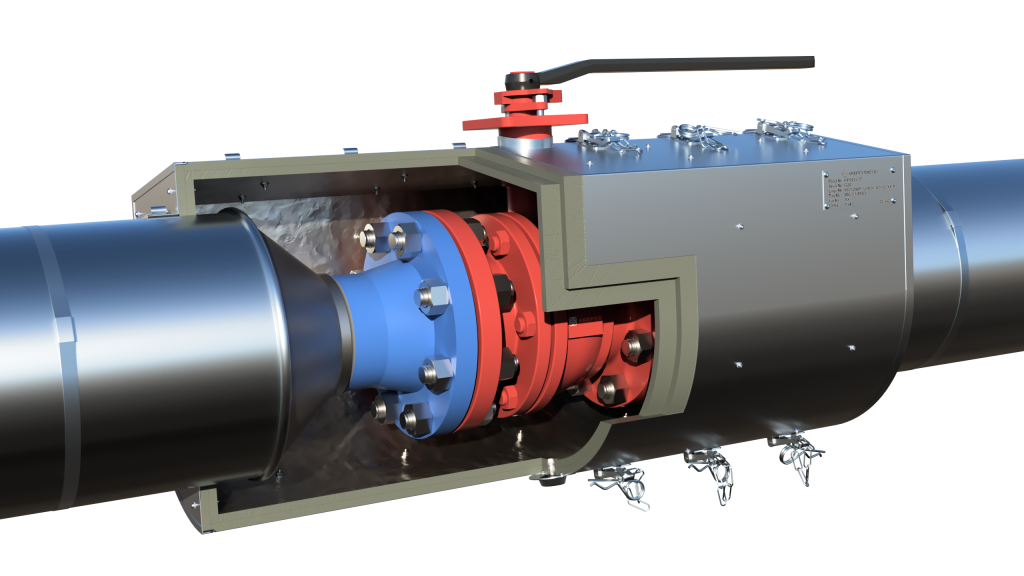

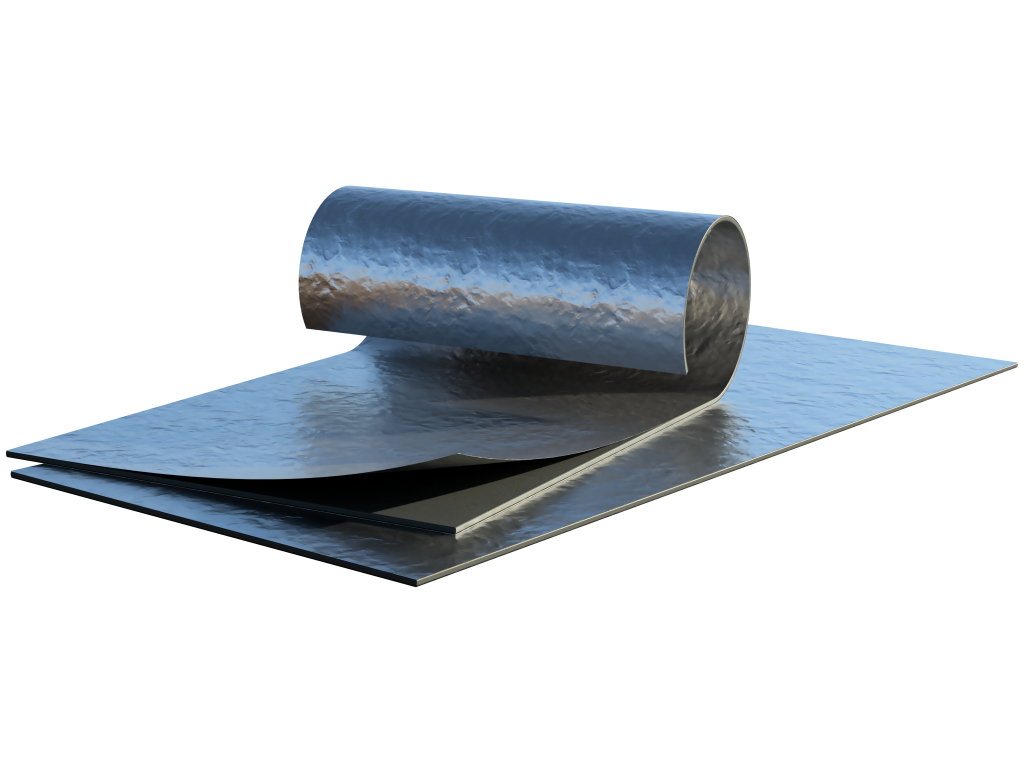

Liquefied Natural Gas (LNG) is a type of cryogenic liquid that can be flammable and can therefore cause jet fires (gas leak ignition). As part of the safety system on LNG vessels, it is required that valves and flanges contain insulation material that protects against both jet fire and cryogenic leakage/spills.