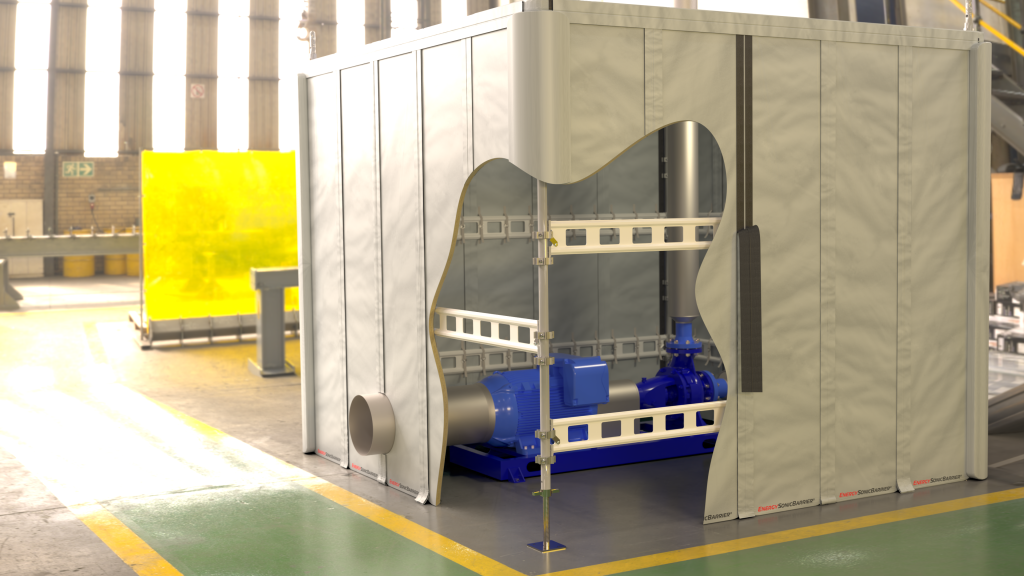

KAEFER is a large, long-term player in the energy market, with many years of experience and expertise in insulation. We are in a unique position to solve complex and comprehensive insulation challenges, which are essential for stable operating conditions, energy efficiency, safety, reduced maintenance and extended lifetime of the customer’s plant and facilities.

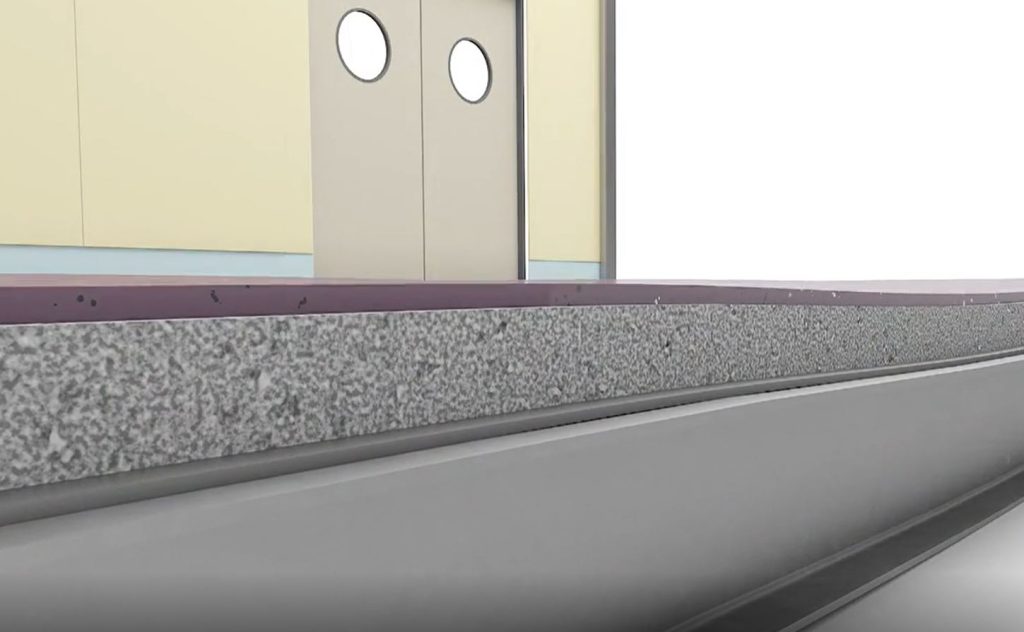

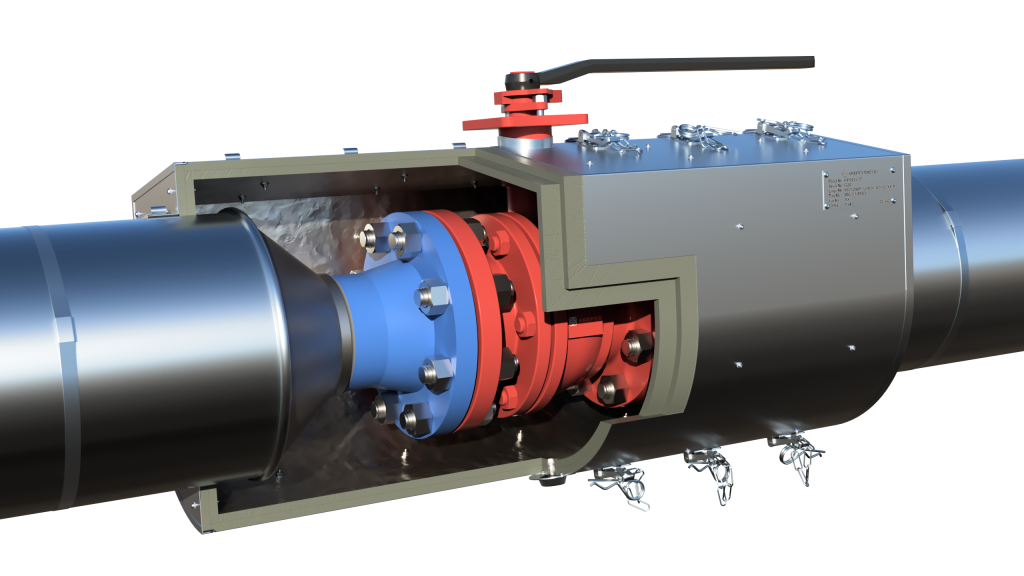

Fire insulation

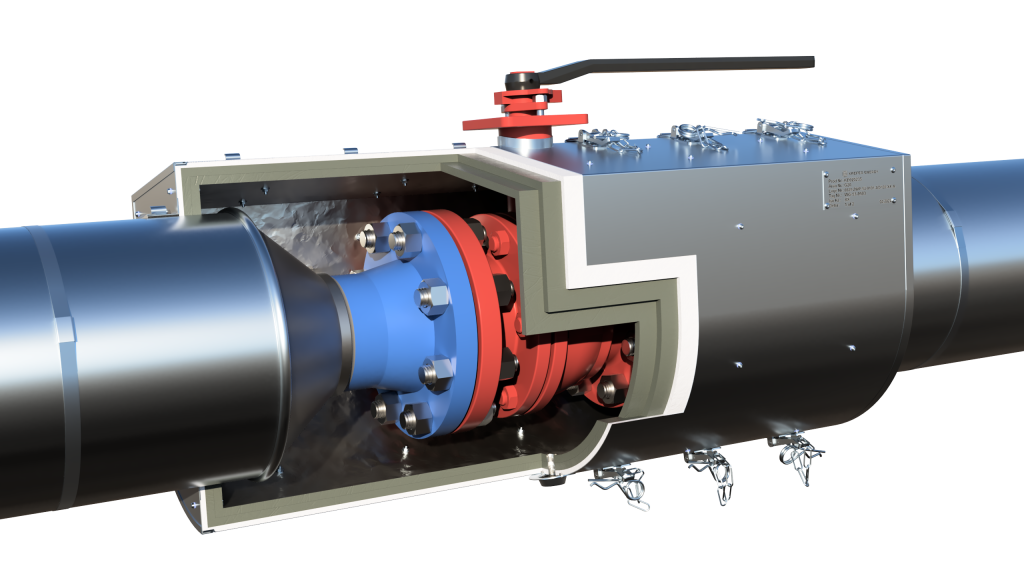

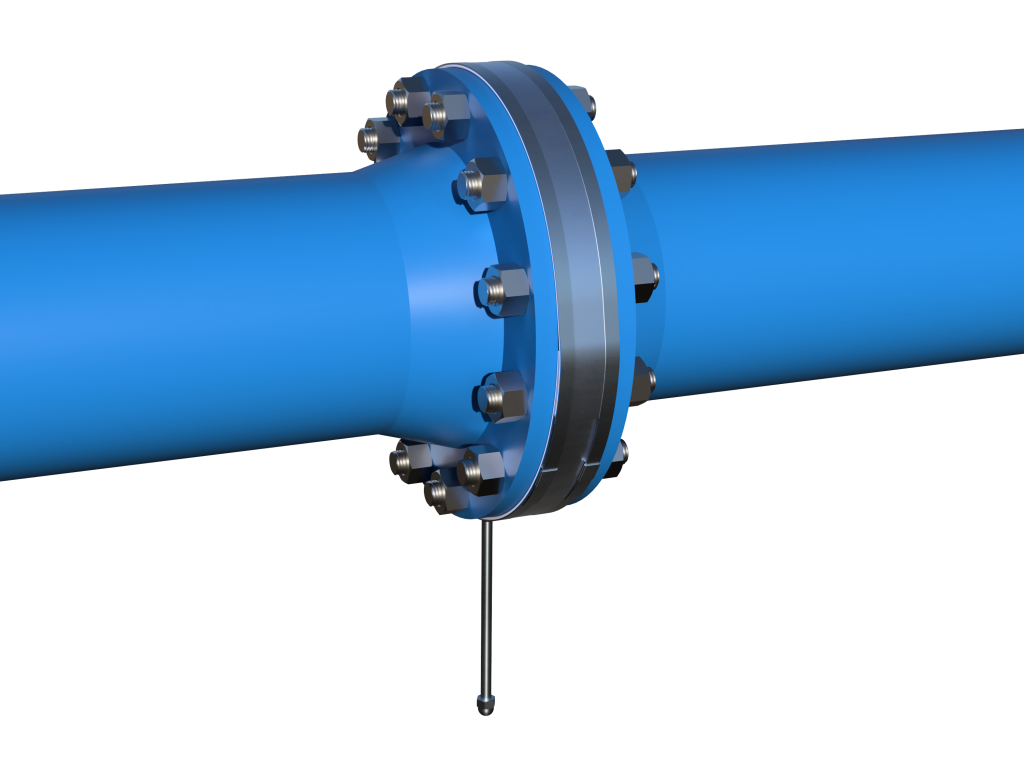

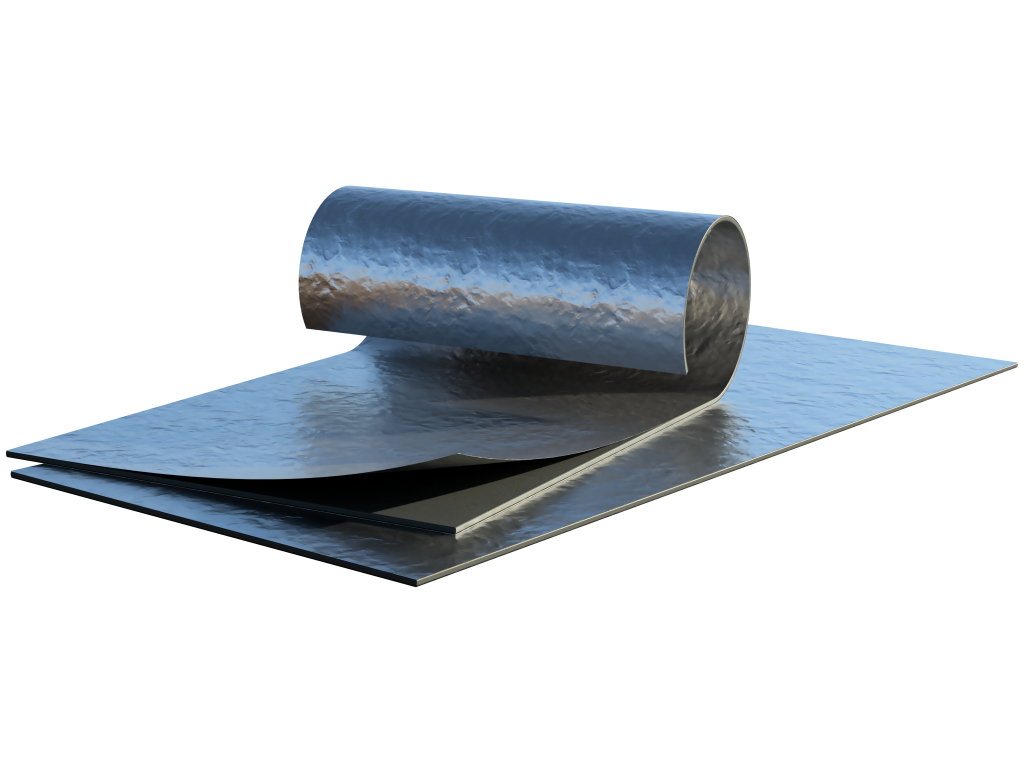

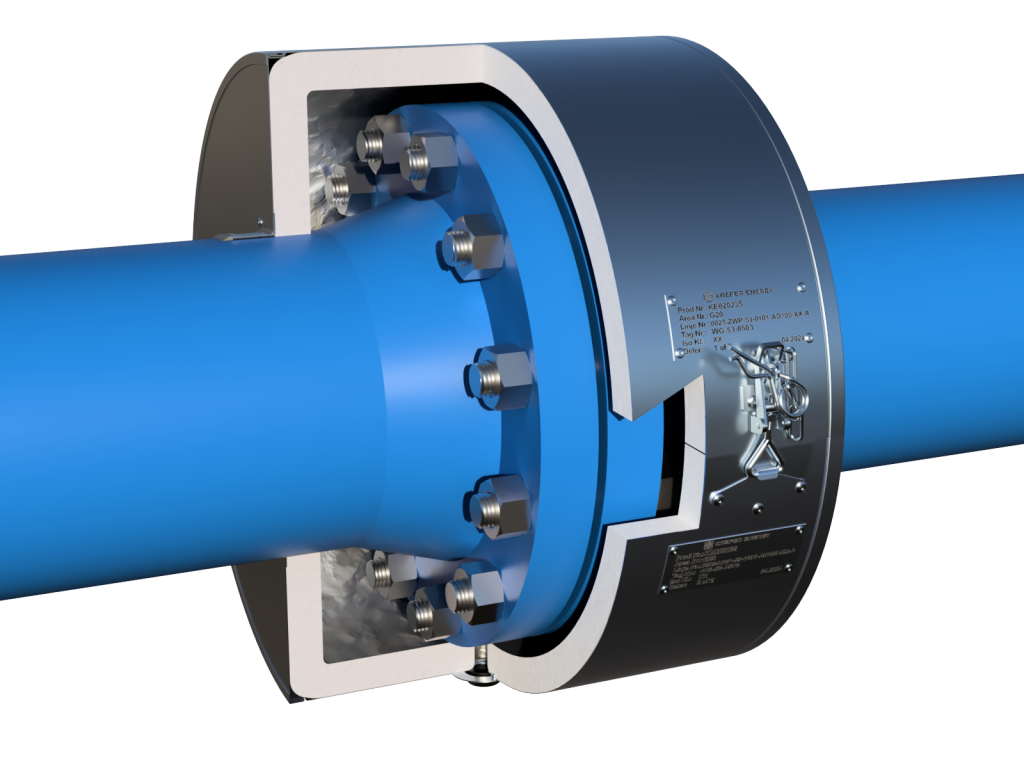

ENERGY Cryocover™

Liquefied Natural Gas (LNG) is a type of cryogenic liquid that can be flammable and can therefore cause jet fires (gas leak ignition). As part of the safety system on LNG vessels, it is required that valves and flanges contain insulation material that protects against both jet fire and cryogenic leakage/spills.